What makes woven badges different from embroidered badges?

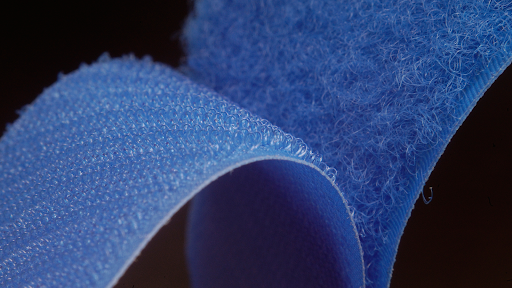

Woven badges are made from thin polyester threads interlaced on a computerised loom, creating designs directly in the fabric. Embroidered badges use thicker threads to stitch onto a backing material, building up layers to form the design.

The differences between the two types of badges become clear when you look at their physical properties:

- Woven badges are thinner, more flexible, and completely flat with no raised texture.

- Embroidered badges have a thicker profile with a dimensional, textured surface where threads sit above the backing.

Woven badges often require no backing material, resulting in smooth designs on both sides. This construction method produces a lightweight, flexible badge that conforms easily to curved surfaces and various fabrics without adding bulk.

Why do woven badges offer better detail for complex designs?

Woven badges excel at reproducing intricate artwork because the weaving process integrates ultra-fine threads directly into the fabric structure, creating sharp lines and precise details that embroidery cannot match. The loom interlaces threads at a density that captures small text, thin borders, and complex patterns with exceptional clarity.

Limitations of Embroidered Badges

Embroidered badges rely on thicker threads stitched onto backing material, which limits their ability to render fine artwork. Text smaller than 3mm often becomes illegible with embroidery, whereas woven badges remain readable at much smaller scales. Custom patches that require subtle gradients or multi-layered logos benefit from the flat, smooth surface that weaving provides.

Advantages of Woven Badges

Colour reproduction reaches professional standards with woven badges. The tight thread integration allows for:

- Crisp colour transitions without bleed

- Accurate Pantone matching for brand consistency

- Sharp contrast between adjacent colours

- Detailed designs with 10+ colours without visual clutter

Corporate logos featuring intricate typography or delicate linework translate perfectly onto woven badges, preserving brand identity with precision that detailed designs demand.

How do woven badges perform in terms of durability and wear?

Woven badges are highly durable and resistant to wear due to their unique construction method. Unlike other badges that are stitched onto a backing material, woven badges have their threads interlaced, making them more robust.

Why are woven badges so durable?

The durability of woven badges comes from their tight weave pattern. This pattern creates a unified fabric structure that resists fraying and ensures the badge lasts longer, even after multiple washes.

Flexibility for different fabrics

One of the key advantages of woven badges is their flexibility. They can easily adapt to various fabric types without cracking or losing shape. This makes them exceptionally comfortable on uniforms, jackets, and curved surfaces where rigid patches might cause discomfort or peel off.

Easy care instructions

Taking care of woven badges is simple:

- You can machine wash them at standard temperatures without worrying about colour bleeding.

- They can be attached using either sewing or heat-sealing methods.

- Woven badges are resistant to fading caused by UV exposure and regular washing.

- Even after hundreds of wash cycles, they maintain a crisp appearance.

Less friction means less damage

Another advantage of woven badges is that they have no raised stitching. This means there is less friction when wearing them, reducing common problems like thread loosening or surface damage that can affect embroidered alternatives.

Are woven badges more cost-effective for bulk or uniform orders?

Woven badges deliver significant savings for organisations placing bulk orders or outfitting entire teams. The manufacturing process requires less material than embroidered alternatives, as the design integrates directly into the fabric without thick backing layers or excess thread.

The streamlined production method enables manufacturers to fulfil large-volume orders efficiently. Cost-effective woven badges become increasingly economical as quantities rise, with per-unit prices dropping substantially for uniform patches across corporate teams or event staff. The precision of automated looms reduces labour time whilst maintaining consistent quality across thousands of pieces.

Organisations benefit from predictable pricing structures when ordering woven badges in bulk. The reduced material costs combined with faster production cycles mean budget-conscious businesses can achieve professional branding without compromising on design complexity or visual impact.

When should an organisation choose woven badges over embroidered ones?

Does your logo contain fine text smaller than 3mm or intricate details with multiple colour transitions? Choosing woven badges becomes essential when design complexity exceeds what embroidery can accurately reproduce. The badge selection criteria shift toward woven options when organisations require a professional, flat finish rather than the raised texture of embroidered patches.

Corporate branding on formal uniforms typically demands the sleek appearance that woven badges provide. Financial institutions, airlines, and hospitality groups select woven options to maintain a polished aesthetic across staff attire. The decision on custom patches depends on whether the application involves lightweight fabrics that cannot support heavier embroidery.

Budget-conscious organisations ordering 500+ units benefit from the efficiency of woven badge production. Promotional items requiring detailed company logos or event-specific designs achieve better visual impact through the weaving process, particularly when distributed at conferences or trade exhibitions.