How Do Iron-On Custom Patches Work and When Are They the Best Option?

Iron on patches, as a form of custom patches, feature a heat-activated adhesive backing that bonds to fabric when exposed to high temperatures from a household iron. The thermoplastic glue melts during application, creating a secure attachment as it cools and solidifies into the fabric fibres.

Application Steps:

-

Position your custom iron on patches on clean, flat fabric

-

Cover with a thin cloth or parchment paper

-

Press a heated iron (no steam) firmly for 15-30 seconds

-

Allow to cool completely before handling

-

Check edges and reapply heat if needed

Custom embroidered iron on patches work brilliantly for casual wear, children's clothing, and quick personalisation projects where permanent sewing isn't practical. They're particularly suited to cotton and cotton-blend fabrics, though woven patch and embroidered patch varieties may require different heat settings depending on their construction.

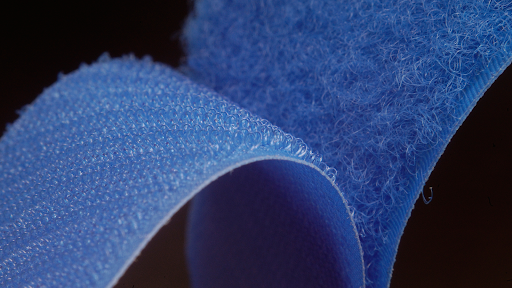

Why Are Velcro Patches Ideal for Swapping, Reusing, or Tactical Gear?

Velcro patches use a hook-and-loop fastener system that consists of tiny hooks on one surface gripping soft loops on the other. This creates an instant attachment that can be easily released with a simple pull. With this mechanism, wearers can quickly swap custom velcro patches without damaging the base fabric or the patch itself.

Benefits for Tactical Gear

Military personnel, law enforcement officers, and outdoor enthusiasts prefer PVC velcro patches for their tactical gear because they can easily change unit identifiers, rank insignia, or morale patches based on mission requirements.

Advantages for Sports Uniforms

Custom team patches with velcro backing are highly effective for sports uniforms, where players frequently switch positions, and for promotional patches that need to be updated throughout a season.

Perks for Children's Clothing

Parents find velcro-backed bulk embroidery patches on children's clothing to be beneficial as they can remove custom made embroidery patches before washing delicate garments or replace designs as interests evolve.

Why Sew-On Custom Patches Are the Most Durable Long-Term Choice

Sew-on patches are more durable than any other attachment method because they use thread to create a permanent bond with the fabric. Unlike iron-on adhesives that can weaken over time or Velcro that loses its grip, custom sew-on patches can withstand hundreds of wash cycles without degrading. This makes them ideal for uniforms, workwear, and items that need frequent washing.

How Sew-On Patches Work

The secret to the durability of sew-on patches lies in how they are attached. The stitching passes through both the patch backing and the garment fibres, spreading the stress across multiple points rather than relying solely on glue. This means that even under heavy use, such as constant rubbing or stretching, the patches stay intact.

The Benefits of Sew-On Patches

Professional teams, military units, and hospitality businesses opt for sew-on custom patches because they know it will save them money in the long run. When patches remain securely stitched for years, there are no replacement costs to worry about. The initial time spent sewing them on pays off with unmatched longevity.

Whether it's industrial washing or exposure to harsh detergents, embroidered sew-on patches maintain their look and feel. They are built to last even in demanding environments where other attachment methods might fail.

In summary, if you're looking for a long-lasting solution for your garments or accessories, sew-on custom patches are the way to go. Their durability and resilience make them the top choice for those who need reliable, durable branding solutions.

What Factors Should You Consider When Choosing Between Iron-On, Velcro, and Sew-On Custom Patches?

The right backingfor your custom patches depends entirely on how you'll use your patches. Custom iron on patches work brilliantly for casual wear and one-time placements where you won't need removal. Velcro patches are ideal for situations that require frequent swapping, like tactical uniforms or children's growing wardrobes. Sew on patches remain the gold standard for permanent, heavy-duty applications.

Fabric type plays a crucial role in your decision for your custom patches. Delicate materials like silk or synthetic blends respond poorly to heat, ruling out custom embroidered iron on patches. Custom PVC patches with velcro backing offer flexibility for technical fabrics found in outdoor gear. Denim, canvas, and cotton accommodate all three attachment methods equally well.

Brand identity considerations matter when selecting custom team patches. Embroidered iron on patches deliver a polished, professional appearance for corporate merchandise. Custom PVC patch designs create modern, eye-catching statements on bags and caps. The attachment method you choose communicates as much about your brand as the design itself.

Which Custom Patch Backing Is Best for Apparel, Uniforms, Bags, or Merchandise?

The right backing for your custom patches depends on how you'll use your custom made embroidery patches. Custom iron on patches suit casual apparel and merchandise requiring quick application, whilst sew on patches deliver unmatched durability for uniforms and bags subjected to frequent washing. Velcro patches work brilliantly for tactical gear and items needing regular patch rotation.

Care varies by type: wash custom embroidered patch items inside out on gentle cycles, hand-clean custom pvc patch products to preserve detail, and store velcro patches separately to prevent hook damage. Bulk embroidery patches for corporate uniforms benefit from professional laundering, whilst custom woven patch designs maintain their appearance with minimal maintenance.

Ready to create patches that perfectly represent your brand? Our team crafts premium custom patches with world-class quality, backed by our 1-year manufacturing warranty and free delivery.