What Are the Key Differences Between Custom Lapel Pins and Acrylic Pins?

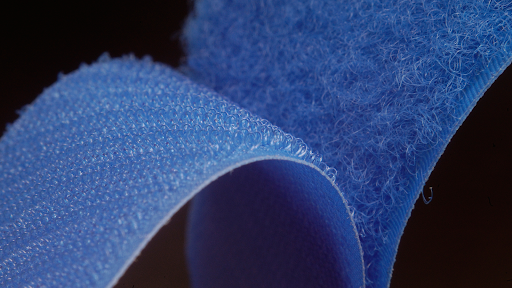

Custom lapel pins feature a metal base with enamel filling, delivering a premium, durable finish that acrylic alternatives cannot match. These luxury custom lapel pins utilise either hard or soft enamel—hard enamel creates a smooth, polished surface ideal for commemorative pins and mens lapel pins, while soft enamel offers a textured, dimensional appearance at a lower price point.

Acrylic pins provide lightweight versatility with vibrant colour reproduction, making custom acrylic pins popular for bold, contemporary designs. The pin acrylic construction allows for photographic-quality prints and translucent effects that metal-based options cannot achieve.

The choice between custom enamel pins and acrylic lapel pins depends on your brand's priorities. Custom lapel pin manufacturers in New South Wales and across Australia craft personalised lapel pins with meticulous attention to heritage and quality, perfect for corporate branding and special events. Acrylic pin manufacturers excel at producing eye-catching, budget-conscious customised pins for promotional campaigns requiring high visual impact.

How Do Soft Enamel and Hard Enamel Lapel Pins Compare to Acrylic Pins in Terms of Durability?

Soft enamel and hard enamel lapel pins significantly outlast acrylic alternatives due to their metal construction and protective coatings. Metal-based enamel pins resist scratches, fading, and general wear, making them the preferred choice for businesses seeking longevity.

Advantages of Enamel Pins Over Acrylic Pins

-

Customisability: Enamel pins offer more design options compared to acrylic pins, allowing for intricate details and vibrant colours.

-

Professional Appearance: Enamel pins have a polished look that exudes professionalism, making them suitable for corporate branding or formal events.

-

Longevity: With proper care, enamel pins can last for years without losing their quality or appeal, making them a cost-effective promotional item in the long run.

Durability of Hard Enamel Pins

Hard enamel pins undergo a polishing process that creates a smooth, glass-like surface flush with the metal edges. This manufacturing technique produces exceptional scratch resistance and maintains its appearance even with daily wear. The pins can withstand harsh Australian climates without colour degradation.

Durability of Soft Enamel Pins

Soft enamel pins feature a textured surface where the enamel sits slightly recessed below the metal lines. Whilst less smooth than hard enamel, they still provide robust durability that far exceeds acrylic options. The raised metal borders protect the enamel from direct impact.

Limitations of Acrylic Pins

Acrylic pins, whilst affordable as alternatives, cannot match the resilience of enamel variants. The lightweight plastic material scratches easily and may crack under pressure. Colours can fade when exposed to sunlight over extended periods.

For campaigns and custom military lapel pins, enamel options deliver quality guarantees through superior materials. The investment in hard or soft enamel ensures pieces maintain their professional appearance throughout years of use, representing your brand with lasting distinction.

When Should You Choose Soft Enamel vs Hard Enamel for Custom Lapel Pins?

Soft enamel suits designs requiring texture and dimension, with recessed enamel creating a tactile surface ideal for custom lapel buttons and promotional campaigns. Hard enamel delivers a smooth, polished finish perfect for luxury custom lapel pins, corporate branding, and custom military lapel pins where a premium appearance matters most.

Soft enamel works best for:

-

Budget-conscious projects seeking custom lapel pins cheap without sacrificing quality

-

Designs with bold outlines and raised metal borders

-

Personalised lapel pins and mens lapel pins for casual events

Hard enamel excels in:

-

High-end commemorative pieces and awards

-

Custom enamel pins require scratch-resistant durability

-

Professional settings demanding refined aesthetics

Local suppliers across South Australia (Adelaide), New South Wales (Sydney), Queensland, and Victoria offer both options with quick delivery, easy returns within 14 days, and secure payment methods. Sourcing custom lapel pins Australia from regional specialists ensures faster turnaround times and direct communication for customised pins tailored to specific brand requirements.

How Does Cost Influence the Choice Between Custom Lapel Pins and Acrylic Pins?

Does price determine which pin style suits your brand best? Acrylic pins custom designs typically cost 30-50% less than enamel alternatives, making them attractive for large-scale promotional campaigns with tight budgets.

An acrylic pin manufacturer can produce custom acrylic lapel pins at a lower cost due to simplified production processes and lower-cost raw materials. Enamel pins require metal bases, multiple firing stages, and skilled craftsmanship, which increase manufacturing costs.

Several factors shift pricing considerations:

-

Design complexity – intricate details and multiple colours increase costs for both types

-

Order quantity – bulk orders reduce per-unit prices significantly

-

Material selection – premium metals and hard enamel command higher prices

-

Production timeline – rush orders typically incur additional charges

Commemorative pins marking significant milestones warrant investment in premium enamel options. These pieces represent your brand's heritage and commitment to excellence, making the additional cost worthwhile for corporate anniversaries, achievement recognition, or special event commemoratives. Budget-conscious brands benefit from acrylic for seasonal promotions or high-volume giveaways where quantity matters more than longevity.

Which Pin Type Offers Better Customisation Options for Brands?

Custom lapel pins excel at detailed embossing and three-dimensional textures, making personalised lapel pins ideal for corporate branding that demands sophistication. Metal enamel allows intricate line work and raised surfaces that convey premium quality.

Custom acrylic pins support complex colour gradients and photographic prints, impossible to achieve with traditional enamel. Pin acrylic materials accommodate full-colour designs with smooth transitions, perfect for vibrant promotional campaigns.

Design capabilities by type:

-

Customised lapel pins: Precision engraving, metal finishes, tactile depth

-

Custom acrylic lapel pins: Unlimited colour options, translucent effects, printed imagery

For special event commemoratives across Australia, luxury custom lapel pins deliver heritage appeal whilst acrylic pin options suit contemporary, graphic-heavy branding. Personalised lapel pin designs benefit from understanding each material's strengths—custom collar pins and custom lapel buttons in enamel project authority. In contrast, acrylic excels at eye-catching visual impact for promotional distribution.